Gas Turbine Services

As a leading independent service provider, Brayton Power Services specializes in value-driven maintenance solutions that maximize performance and efficiency

Currently Servicing

GE Frame 3,5,6,7

Alstom GT8, GT11

Our field service offering include

- Outage management & major overhaul

- Routine inspection & repairs

- Borescope inspection

- Removal, installation & commissioning of mechanical equipment

- Fault finding & controls diagnostics

- On site machining & balancing

- Optical & laser alignment

- Heavy rigging & transportation

- Generator Testing and Repair

Boroscope Inspection

A borescope inspection service uses a boroscope to remotely visualize the internal components of machinery, such as pipes, compressor or turbine sections. This allows technicians to inspect for defects like corrosion, cracks, and blockages without complete disassembly. Borescopes can be flexible or rigid and are equipped with a camera and light at one end, transmitting images to an operator.

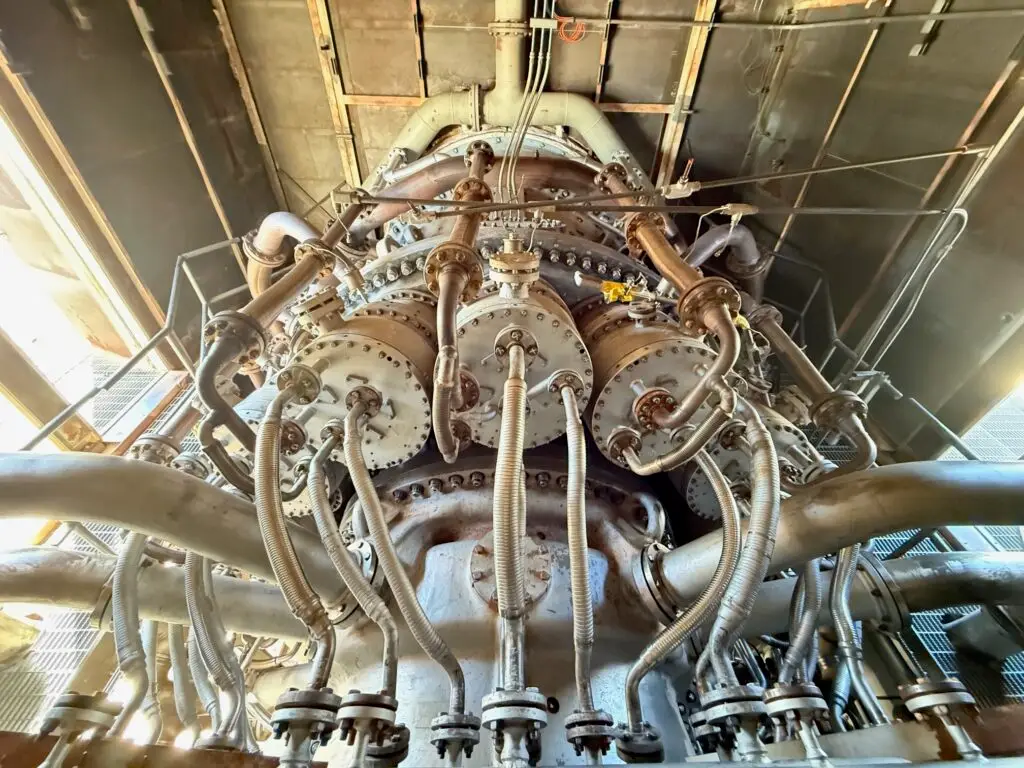

Hot Gas Path

A comprehensive inspection and maintenance procedure focused on components exposed to high temperatures and combustion gases—such as nozzles, liners, transition pieces, and buckets. The goal is to detect wear, damage, or other issues that could affect turbine performance and lifespan, and to install new components as needed.

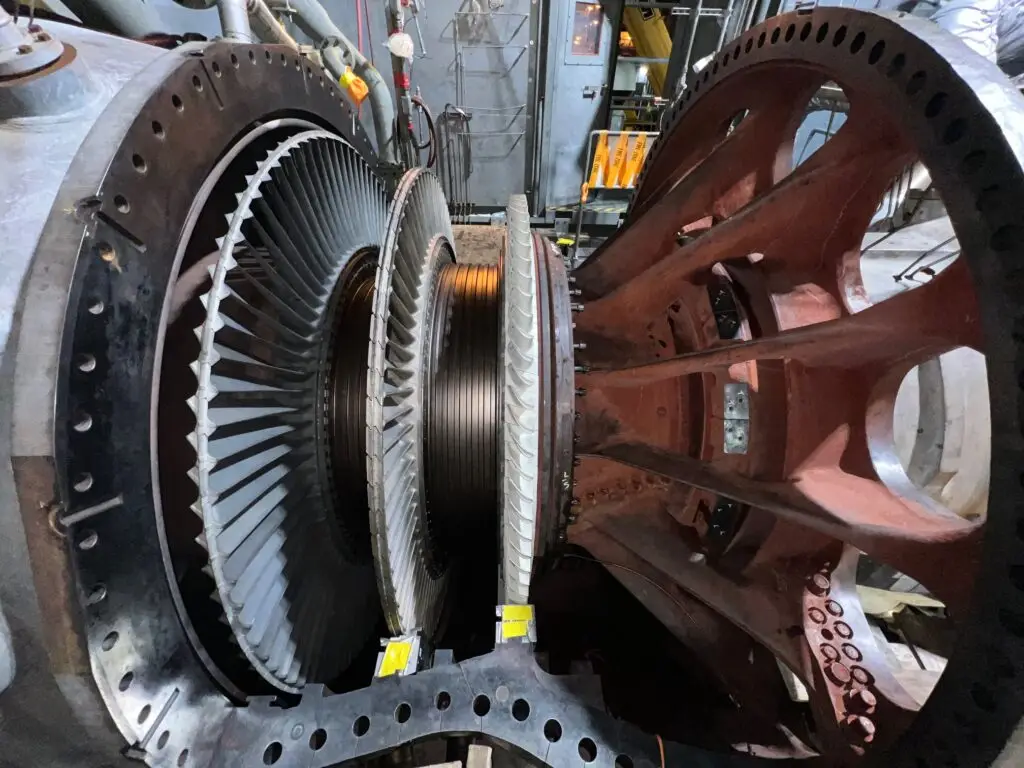

Major Inspection

A thorough evaluation of internal components—from the inlet to the exhaust—including the hot gas path, compressor, bringing the rotor-out, and redoing bearings. Performed at scheduled intervals or based on component condition, it assesses wear, damage, and overall system integrity to ensure reliable performance.

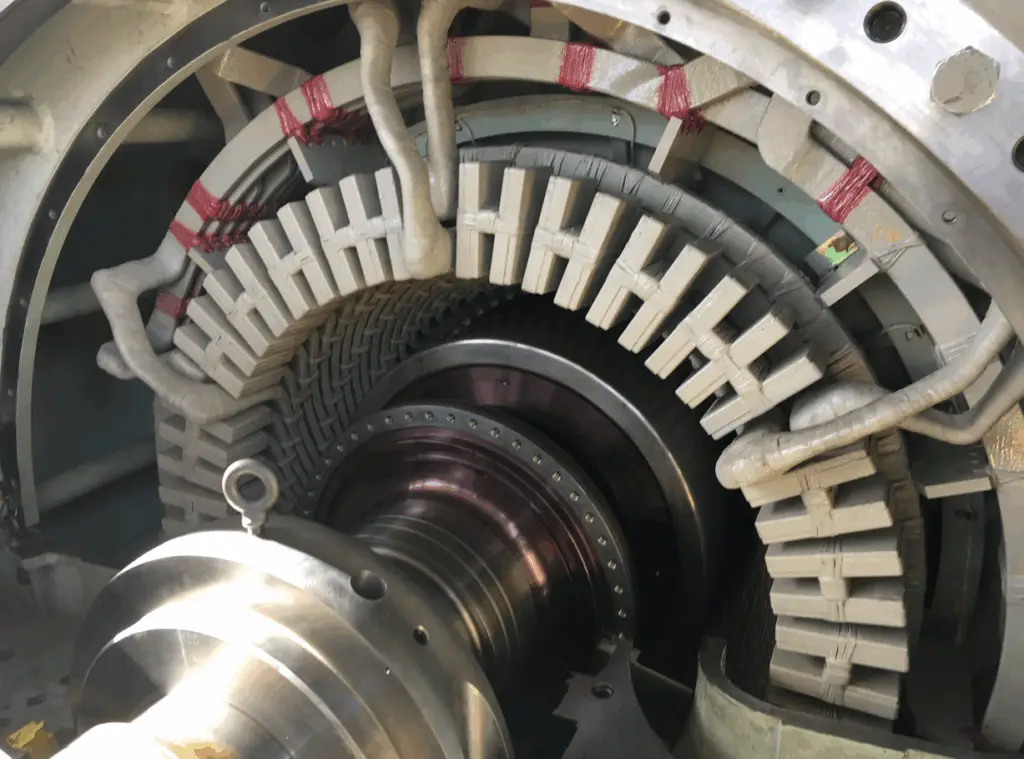

Gas Generator Inspection

Generator testing and inspections help ensure reliable, safe, and efficient operation by identifying and addressing potential issues before failures occur. The process involves detailed evaluations, including visual inspections, performance tests, and electrical assessments, to optimize performance and extend equipment lifespan.